Welcome to our insightful blog from BizzAppDev. In today's post, we’ll discuss how Odoo simplifies manufacturing with the One-Step Manufacturing Process. Whether you’re a small business or a large enterprise, understanding how to manage your manufacturing orders effectively in Odoo can greatly improve efficiency and reduce operational time.

What is One-Step Manufacturing?

In Odoo, One-Step Manufacturing is designed to simplify the manufacturing process by allowing you to create a manufacturing order and directly update your inventory without needing separate transfer orders for raw materials and finished products. This feature optimizes workflow, reducing complexity, and ensuring smoother operations.

In the traditional manufacturing process, companies would create separate transfer orders for components (raw materials) and finished products. But with One-Step Manufacturing in Odoo, once you confirm the manufacturing order, the inventory is updated automatically, eliminating the need for extra steps. Let’s dive into the step-by-step process to see how you can manage your manufacturing operations efficiently using this feature.

Steps to Manage One-Step Manufacturing in Odoo

Step 1: Configuration

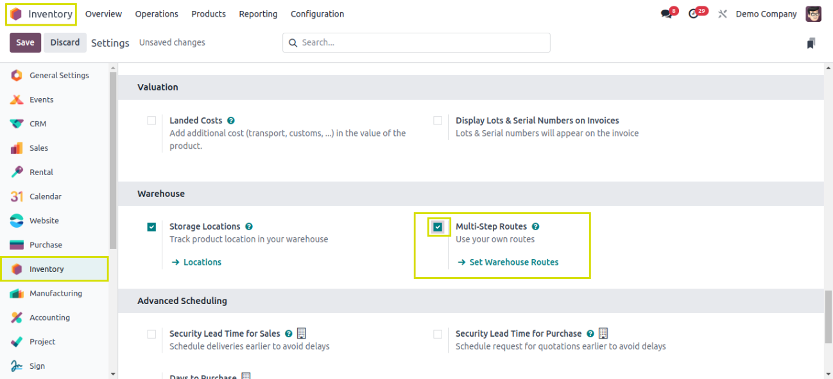

To get started, make sure that the multi-step routes are enabled under the Warehouse module. This feature allows you to customize the routes for different products, enabling you to define how your goods move across warehouses.

- Navigate to the Inventory module and check that the Multi-Step Routes option is enabled.

(Odoo Apps > Inventory > Configuration > Warehouse > Enable Multi-Step Routes)

- Once enabled, the manufacturing process becomes simplified, as you don’t have to manage multiple transfer orders manually.

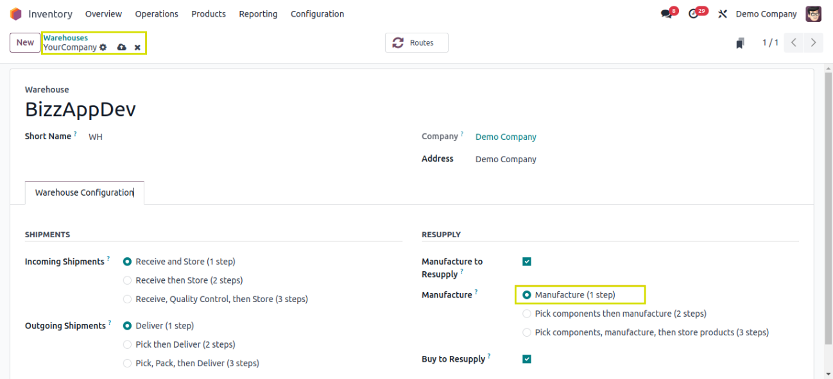

(Inventory > Configuration > Warehouse > Select Your Warehouse)

Step 2: Define Manufacturing Orders

After configuring the routes, the next step is to define your Manufacturing Orders (MO). These orders are generated based on your product’s Bill of Materials (BoM). Let’s walk through the process:

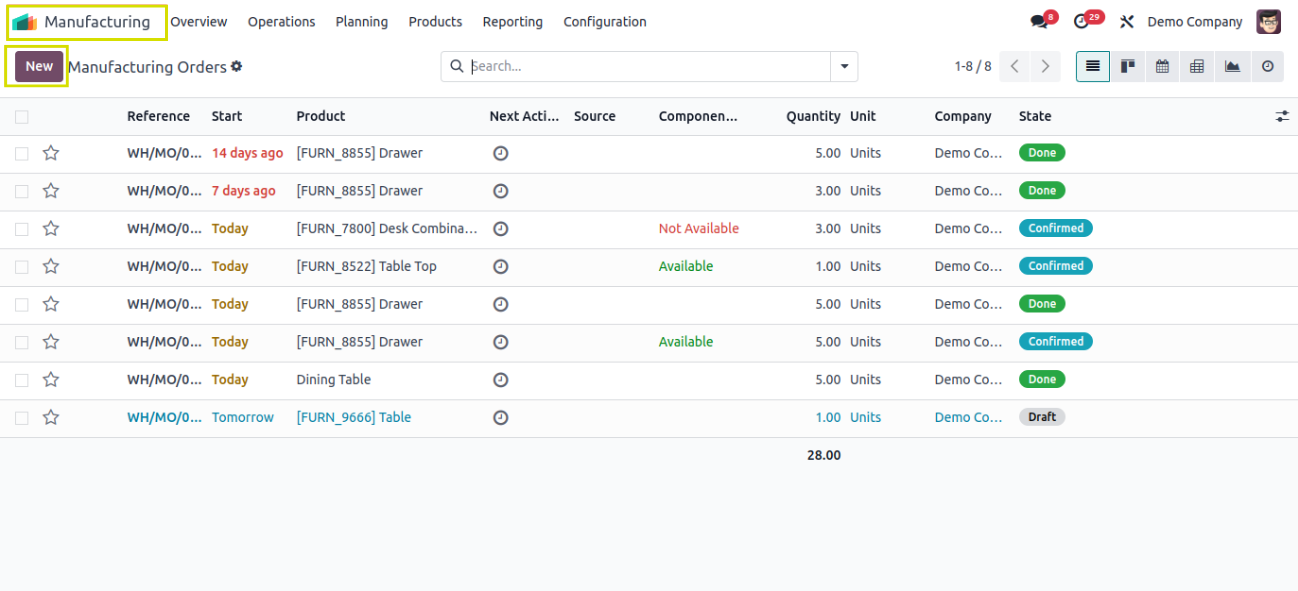

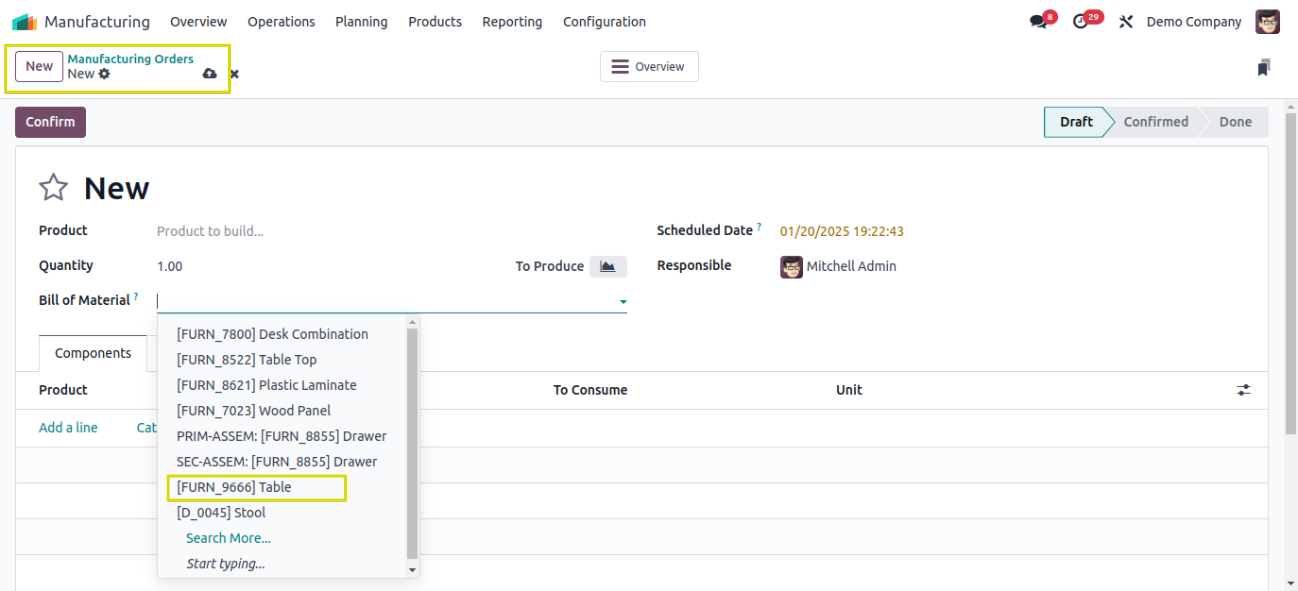

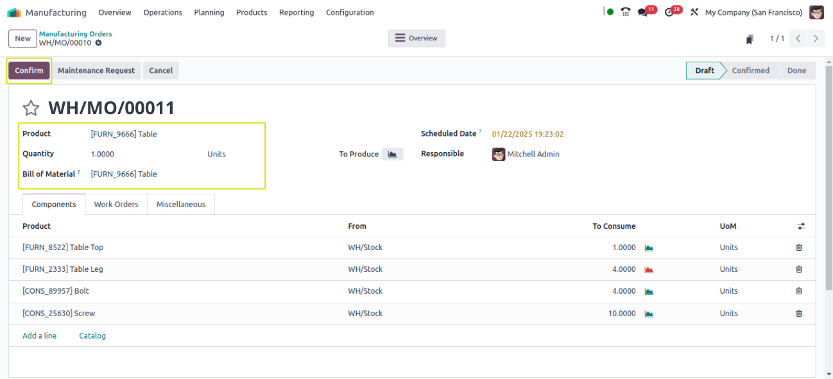

1. Create a New Manufacturing Order:

(Manufacturing > Operations > Manufacturing Orders > New)

- Select your product (e.g., a table).

- Choose the Bill of Materials (BoM), which includes all the components required for production (e.g., table top, legs, screws, etc.).

- Define the quantity for production.

- The product details will auto-populate based on your configuration.

(Manufacturing Orders > New > Fill Up Details)

2. Confirm the Order:

- Once you confirm the order, the status of the manufacturing process will show as Ready.

- The system will automatically create the required operations and transfer orders for all component.

(Manufacturing Orders > New > Fill Up Details > Confirm)

Step 3: Start the Manufacturing Process

Once the manufacturing order is confirmed, you can proceed with the production process. Here’s where One-Step Manufacturing truly shines:

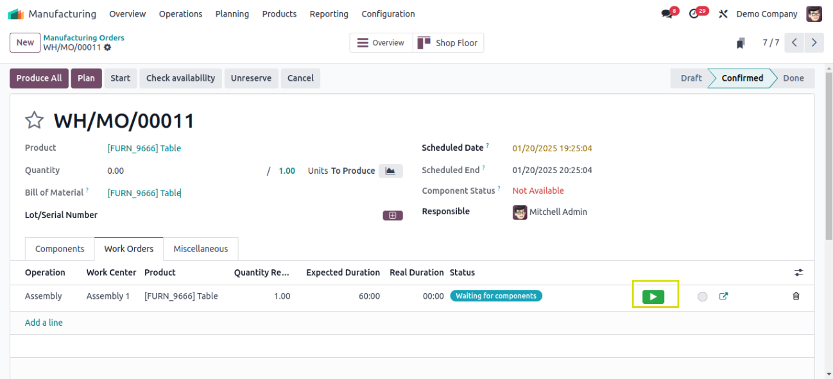

1. Track Operations:

- The manufacturing system will calculate the actual duration of each operation.

- Odoo will prompt you to complete different stages of production (e.g., assembly, quality checks, etc.).

- Each operation will be validated as you move forward.

(Manufacturing Orders > New > Fill Up Details > Confirm > Work Orders > Start Producation)

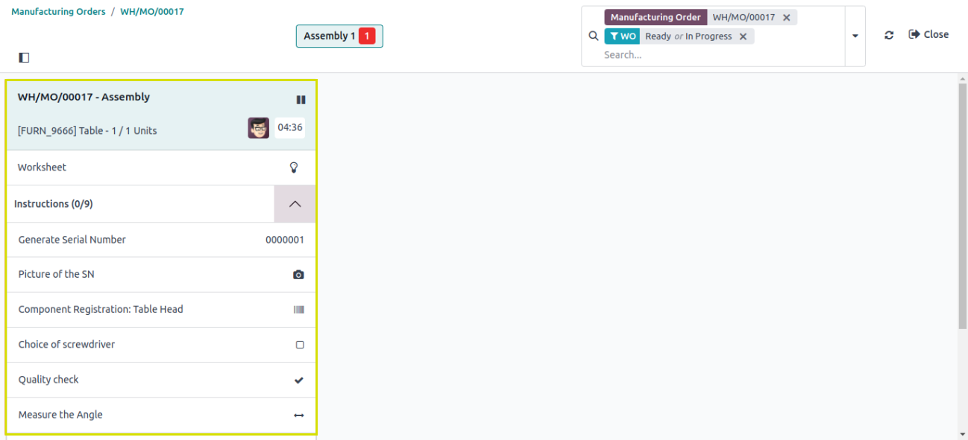

2. Quality Check:

- Odoo allows you to set up quality checks for each stage.

- For example, before assembling the legs to the table, you can validate that all parts are in good condition and meet the required quality standards.

- If everything is fine, you proceed with the next stage. If any issue is detected, you can mark it as Failed.

(Manufacturing Orders > Shop Floor > Assembly)

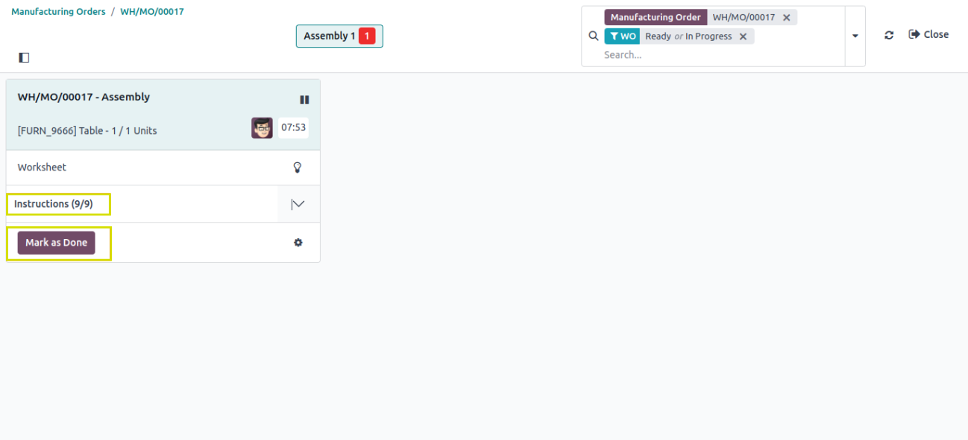

3. Complete Assembly:

- After assembling the table, mark the operation as complete.

- The system will update the inventory, and the finished product (e.g., the assembled table) will now be available in your stock.

(Manufacturing Orders > Shop Floor > Assembly > Instructions)

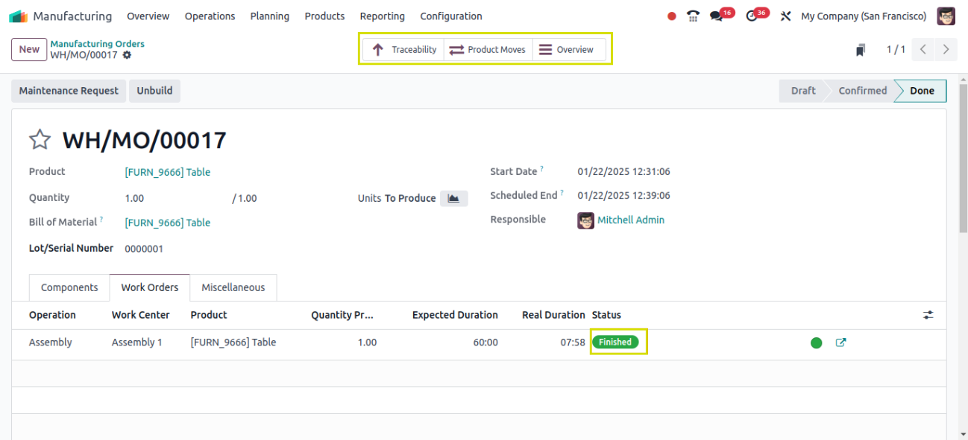

Step 4: End the Manufacturing Order

Once all operations are completed and quality checks are validated, you can finalize the manufacturing process:

1. Confirm Product Movement:

- The system will show the movement of the product across your warehouse, ensuring all materials and finished goods are properly tracked.

2. Cost Calculation:

- Odoo will also calculate the unit cost and real cost of the manufactured item. This includes costs for components like the table top, legs, and screws.

- You can track these costs in the Product Overview, providing clear insights into your production expenses.

(Manufacturing Orders > Overview > Tracebility)

Benefits of One-Step Manufacturing in Odoo

Time-Saving:

One-step manufacturing helps streamline your production process by eliminating unnecessary steps. Your inventory is updated in real-time, reducing delays in tracking components and finished products.

Efficient Production:

With Odoo, the manufacturing order automatically includes the required components and operations, allowing you to focus on what truly matters—production.

Improved Inventory Management:

Odoo’s seamless integration between manufacturing and inventory ensures that your stock levels are always accurate and up-to-date.

Customization:

If needed, you can also customize the workflow to suit your specific manufacturing needs, making the entire process more flexible.

Final Thoughts

The One-Step Manufacturing feature in Odoo is a game-changer for businesses looking to improve their manufacturing processes. By enabling a seamless connection between inventory and manufacturing orders, businesses can save time, improve productivity, and ensure better resource management.

At BizzAppDev, we specialize in Odoo Customization and can help you tailor Odoo to suit your unique business needs. If you want to learn more or get personalized assistance with Odoo, feel free to contact us.

Thank you for reading! Stay tuned for more Odoo tutorials and tips.

Feel free to reach out to us for Odoo customization and support. Stay awesome and keep improving your business processes with Odoo!

Take Your Manufacturing to the Next Level with Odoo!

Related Blogs